Ultra Sonic Cleaning

We can offer servicing and cleaning of cylinder wash units and other components.

Ultra Sonic Cleaning

The item to be cleaned will be stripped down and the worst of the contamination cleaned off by hand. Hand cleaning means we use fewer chemicals thus making the cleaning process more environmentally friendly. Following the hand cleaning the bearings, brush rollers, tubes, blades etc will be checked for wear.

All parts are then cleaned using our Ultra Sonic cleaning system which uses specially formulated chemicals and ultra-sonic vibrations then break down the contaminants leaving the item spotlessly clean.

After rinsing and a further inspection, the item will be reassembled, and new parts fitted as required.

We offer a service exchange system where we can loan a reconditioned cartridge while your one is being cleaned and serviced. This enables you to stay in production with minimum downtime and inconvenience.

You will find our prices very competitive and be confident that all work undertaken is carried out on our premises and not passed to a third party.

We are also able to clean many other press components which are heavily inked up or contaminated, such as gripper bars, ink cups and coating rollers etc.

We would be able to give you a competitive quotation for any type of work you require to be carried out. Simply fill out our contact page or give us a call.

From our gallery

How can we help...

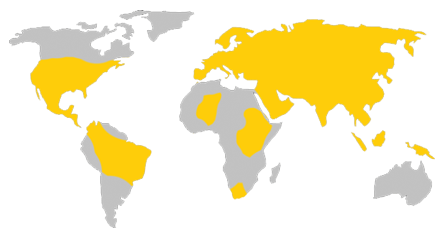

We are located in the south of England however we operate in over 70 countries worldwide. See the full list.